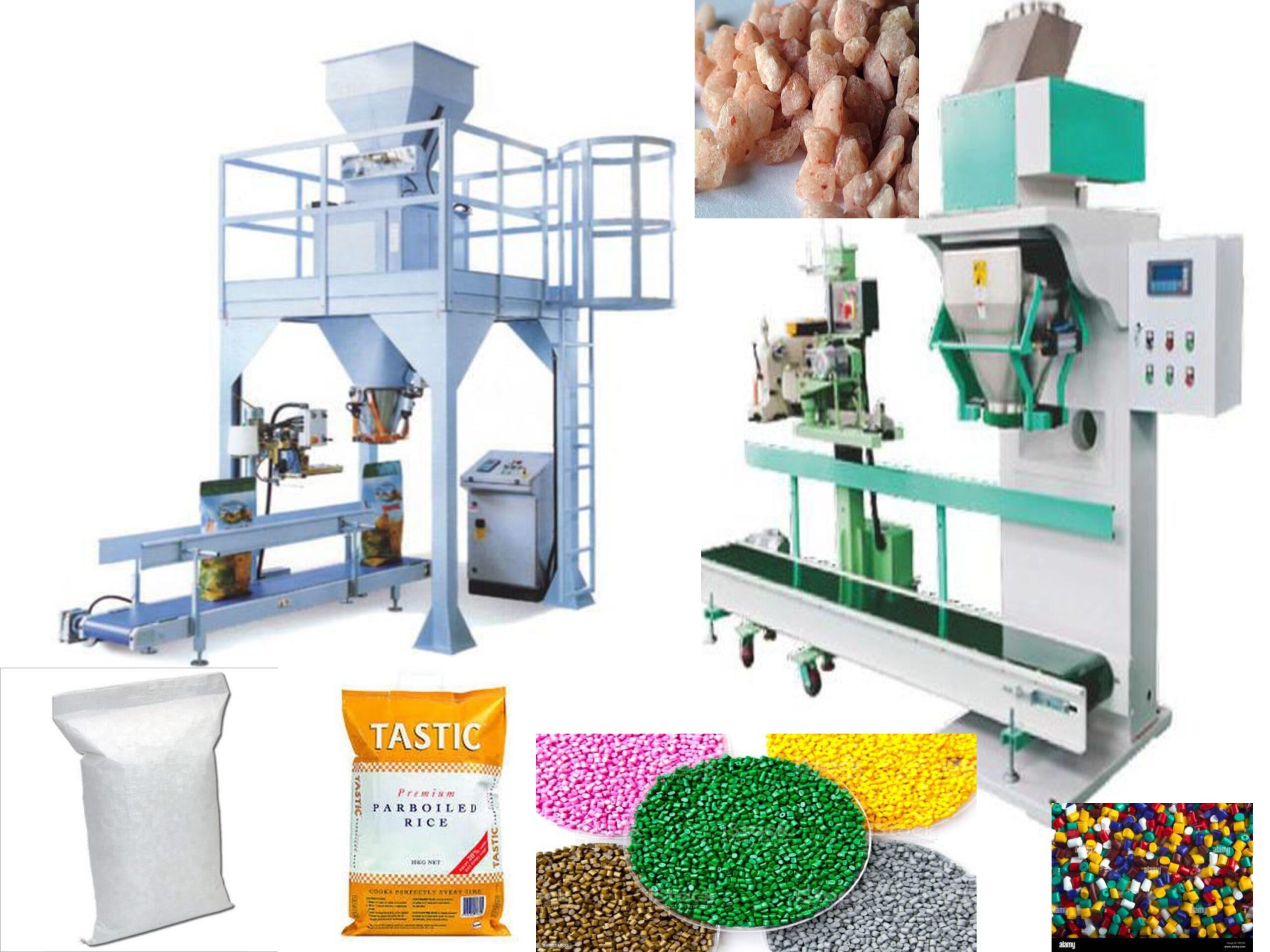

25 kg polymer bag packing machine

25 kg polymer packing machine is designed for efficient packaging of polymer materials in 25 kg bags. Key features may include:

1. Weighing System: Precise weighing scales or load cells ensure accurate measurement of polymer quantities for each bag.

2. Bag Handling: Automated bag feeding and placement mechanisms streamline the process, improving efficiency.

3. Bag Opening: Mechanisms for opening bags, whether through cutting or other methods, ensure a consistent and reliable start to the packaging process.

4. Filling Mechanism: The machine dispenses the polymer material into bags, and the filling process can be optimized for speed and accuracy.

5. Sealing Options: Various sealing methods, such as heat sealing or sewing, secure the filled bags, maintaining the integrity of the packaged polymer.

6. Material Handling: Efficient conveyors move the filled bags through different stages of the packaging line, ensuring a smooth workflow.

7. Quality Control: Sensors and inspection mechanisms may be incorporated to identify and reject improperly filled or sealed bags, ensuring product quality.

8. Flexibility: Adjustable settings allow the machine to accommodate different bag sizes and types, providing flexibility for various packaging needs.

9. Labeling and Coding: Integration with labeling and coding systems enables the application of necessary information on the bags for traceability and identification.

10. Automation: Centralized control systems automate the packaging process, reducing manual labor and increasing overall efficiency.

These features collectively contribute to a reliable and efficient packaging process tailored for 25 kg polymer bags.