Automated bagging machine manufacturer

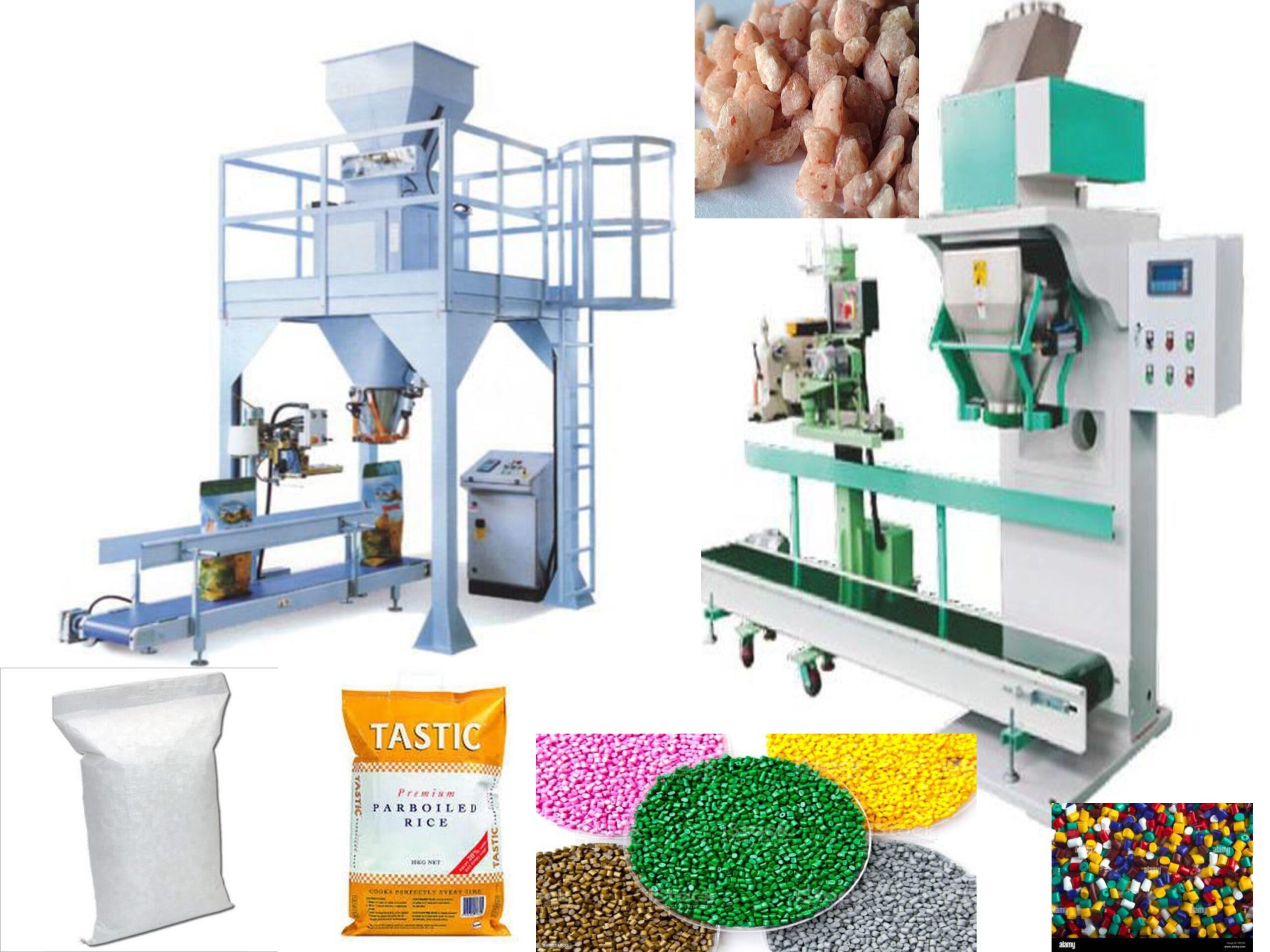

Vista Packing and Conveying Solutions specializes in manufacturing automated bagging machines designed to streamline the packaging process. Our machines fill and seal bags with precision and efficiency, catering to various industries’ needs.

Key Features

1. Automated Filling and Sealing: Our machines automatically fill bags with a precise quantity of product and then seal them, significantly improving efficiency and reducing labor costs.

2. High-Speed Operation: Capable of processing numerous bags per minute, our machines boost productivity in high-demand environments.

3. Accuracy and Consistency: Equipped with advanced weighing and measuring systems, our machines ensure each bag contains the exact amount of product, minimizing waste and ensuring consistency.

4. Versatility: Our machines are suitable for various bag types (e.g., plastic, paper, woven) and sizes, accommodating different product types and packaging requirements.

5. Customizable Options: We offer customization with different feeding systems, sealing mechanisms, and printing options for product information or branding.

6. Integration Capabilities: Our machines can be integrated with other automation systems, such as conveyors, palletizers, and quality control systems, creating a seamless packaging line.

7. User-Friendly Interface: Featuring intuitive control panels or touchscreen interfaces, our machines are easy to operate and adjust.

8. Safety Features: Equipped with safety interlocks, emergency stops, and protective guards, our machines ensure operator safety.

Applications

1. Food Industry: Ideal for packaging grains, flour, sugar, snacks, frozen foods, and other edible products, ensuring hygienic and contamination-free packaging.

2. Agricultural Products: Perfect for bagging seeds, fertilizers, animal feed, and other agricultural products.

3. Chemical Industry: Suitable for packaging powders, granules, and other chemical products, ensuring precise dosing and safe handling.

4. Construction Materials: Used for bagging cement, sand, aggregates, and other building materials.

5. Retail Goods: Employed for packing consumer goods like pet food, charcoal, potting soil, and more, enhancing product presentation and convenience for end-users.

6. Pharmaceuticals: Ensures precise packaging of powders and granules used in the pharmaceutical industry, maintaining strict hygiene and dosage standards.

7. Recycling and Waste Management: Used for bagging recycled materials or waste products, aiding in efficient waste management and recycling processes.

Benefits

• Increased Efficiency: Automated processes reduce the time and labor required for packaging, leading to higher throughput.

• Cost Savings: Minimizes labor costs and product wastage, achieving significant savings.

• Improved Accuracy: Ensures consistent product weight and quality, which is critical for customer satisfaction and regulatory compliance.

• Scalability: Easily scalable to meet growing production demands without significant increases in labor costs.

• Enhanced Safety: Reduces the need for manual handling, thus minimizing the risk of injury to workers.

For more information about our automated bagging machines, contact Vista Packing and Conveying Solutions:

• Phone: +91-7567613811

• Email: sales@vistapacking.com

• Website: www.vistapacking.com

Discover how our advanced packaging solutions can optimize your production line today.