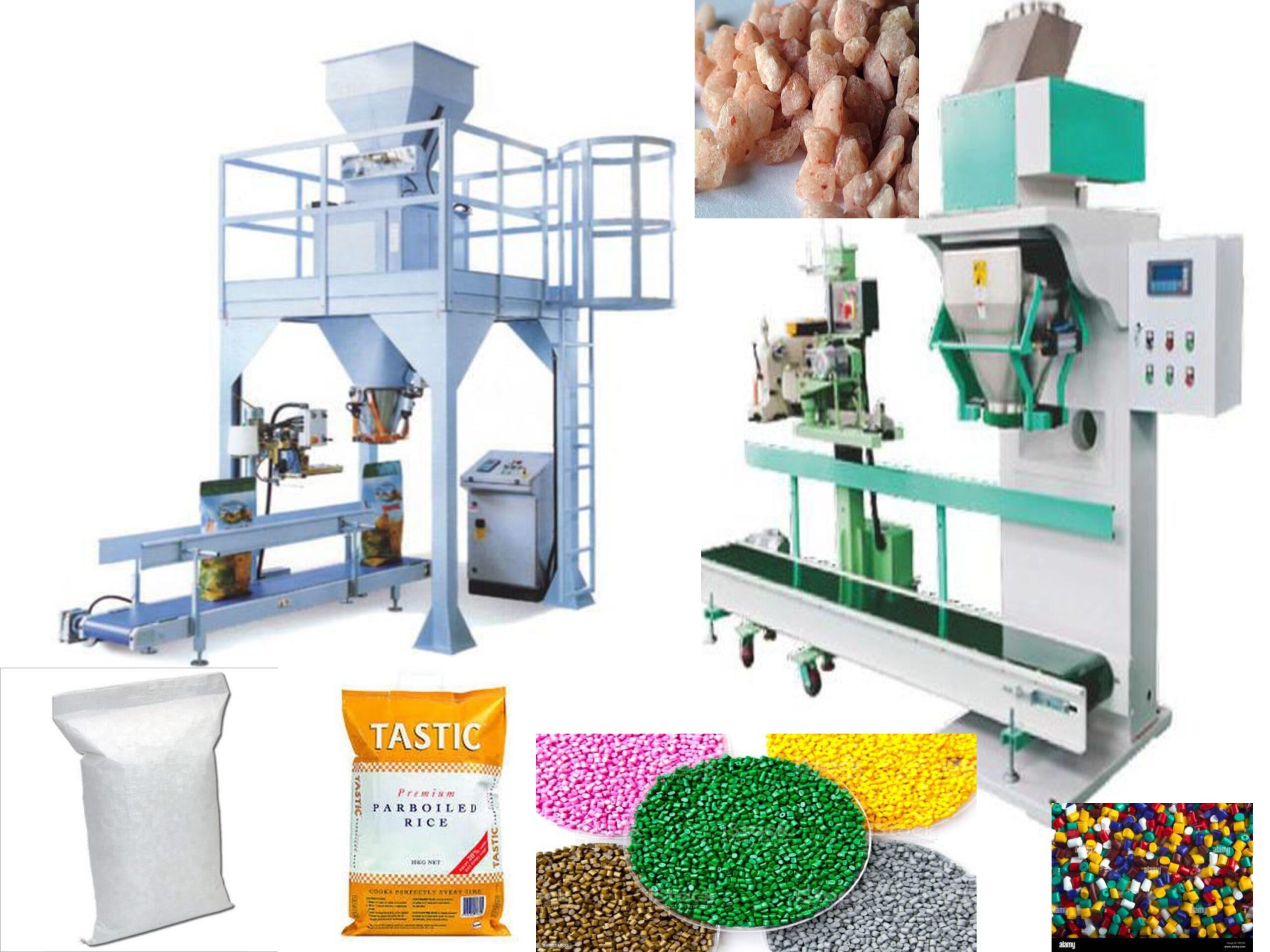

powder filling system

Description Features:

Optimize your powder packaging with our advanced powder filling system—a precise and efficient solution for various powdered materials. Versatile and adaptable, it ensures accurate filling, minimizing waste, and maximizing production efficiency. With customizable features and user-friendly controls, this system streamlines the powder packaging process.

Product Specification:

• Filling Speed: Adjustable for optimal production rates

• Maximum Fill Weight: Tailored to accommodate varying powder densities

• Material Compatibility: Versatile, suitable for a wide range of powdered materials

• Filling Accuracy: ±0.2% precision for meticulous measurements

• Filling Mechanism: Auger-based or gravity-fed, adapting to material characteristics

• Hopper Capacity: Customizable to meet specific production needs

• Construction: Robust design for durability in industrial settings

• Customization Options: Adjustable for different packaging sizes and materials

• Control System: PLC-based controls with a user-friendly interface

• Safety Features: Emergency stop, safety interlocks, compliance with industry standards

• Power Requirements: Three-phase, 380V AC, ensuring reliable power supply for continuous operation.