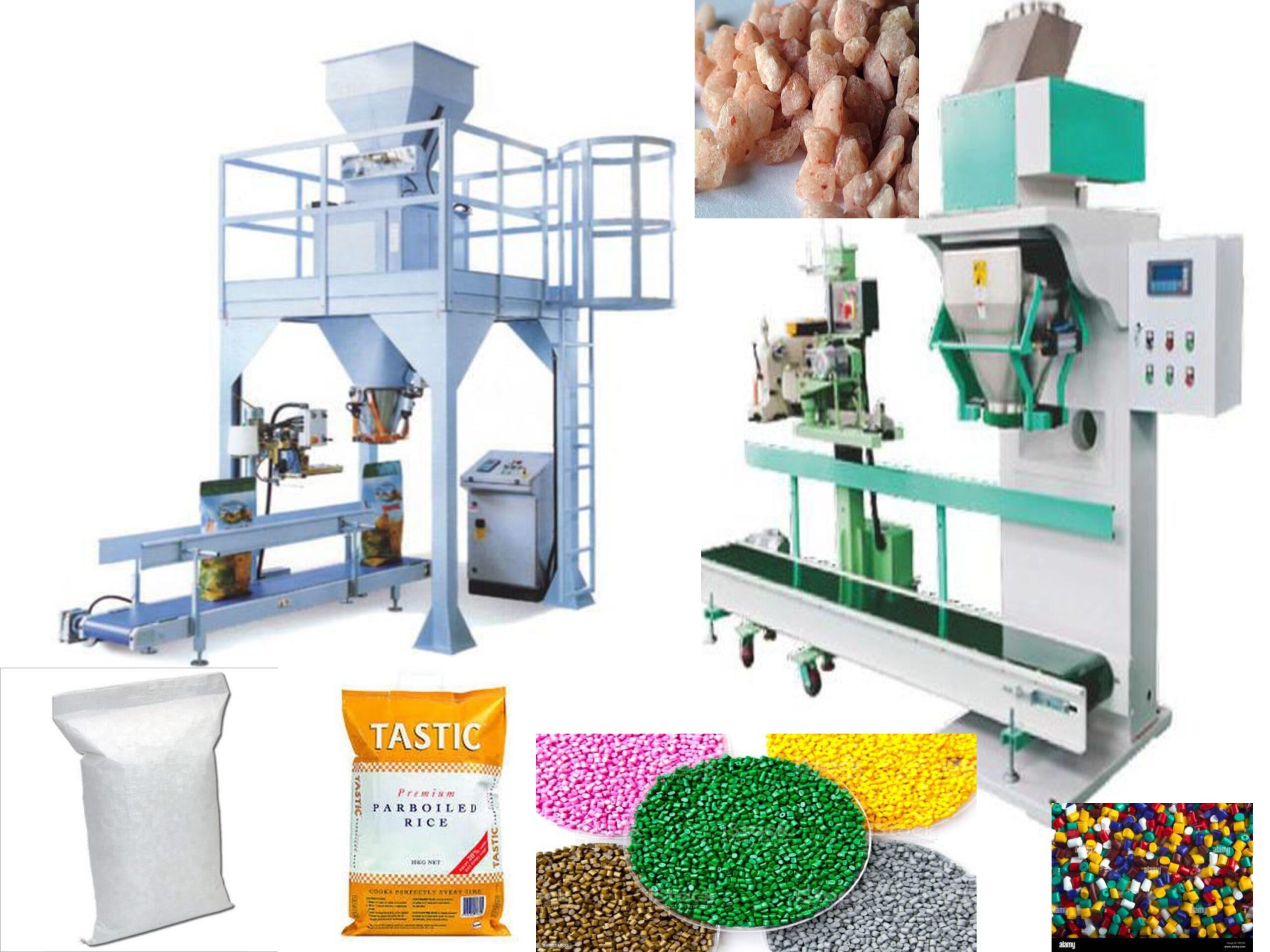

Weighing And Filling machine

Weighing and filling machines are advanced systems designed to accurately measure and dispense specific quantities of products into containers. Here are key features of these machines:

1. *Precision Weighing Technology:* Utilizes high-precision weighing mechanisms to ensure accurate measurement of product quantities, maintaining consistency in packaging.

2. *Versatility:* Suitable for a diverse range of products, including granules, powders, liquids, and more, making them adaptable to various industries.

3. *Automated Filling:* Efficient automation of the filling process, reducing manual labor and enhancing overall production efficiency.

4. *Customizable Dosage:* Adjustable settings allow for precise control over the dosage, accommodating different packaging requirements and product specifications.

5. *User-Friendly Interface:* Intuitive control panels make operation straightforward, enabling easy adjustments, monitoring, and maintenance.

6. *Integration Capabilities:* Designed to seamlessly integrate into existing production lines, ensuring a smooth and synchronized manufacturing process.

7. *Accurate Sealing Mechanisms:* Ensures the accurate and secure sealing of containers, maintaining product integrity and preventing contamination.

8. *Durable Construction:* Built with robust materials, these machines withstand the rigors of industrial use, providing longevity and reliability.

9. *Safety Features:* Equipped with safety measures like emergency stops and sensors, prioritizing operator well-being and maintaining a secure working environment.

10. *Data Recording and Reporting:* Some models offer data recording capabilities, allowing businesses to track production metrics and ensure quality control.

Weighing and filling machines are indispensable for businesses seeking precise, efficient, and customizable solutions for their packaging needs across various product types.