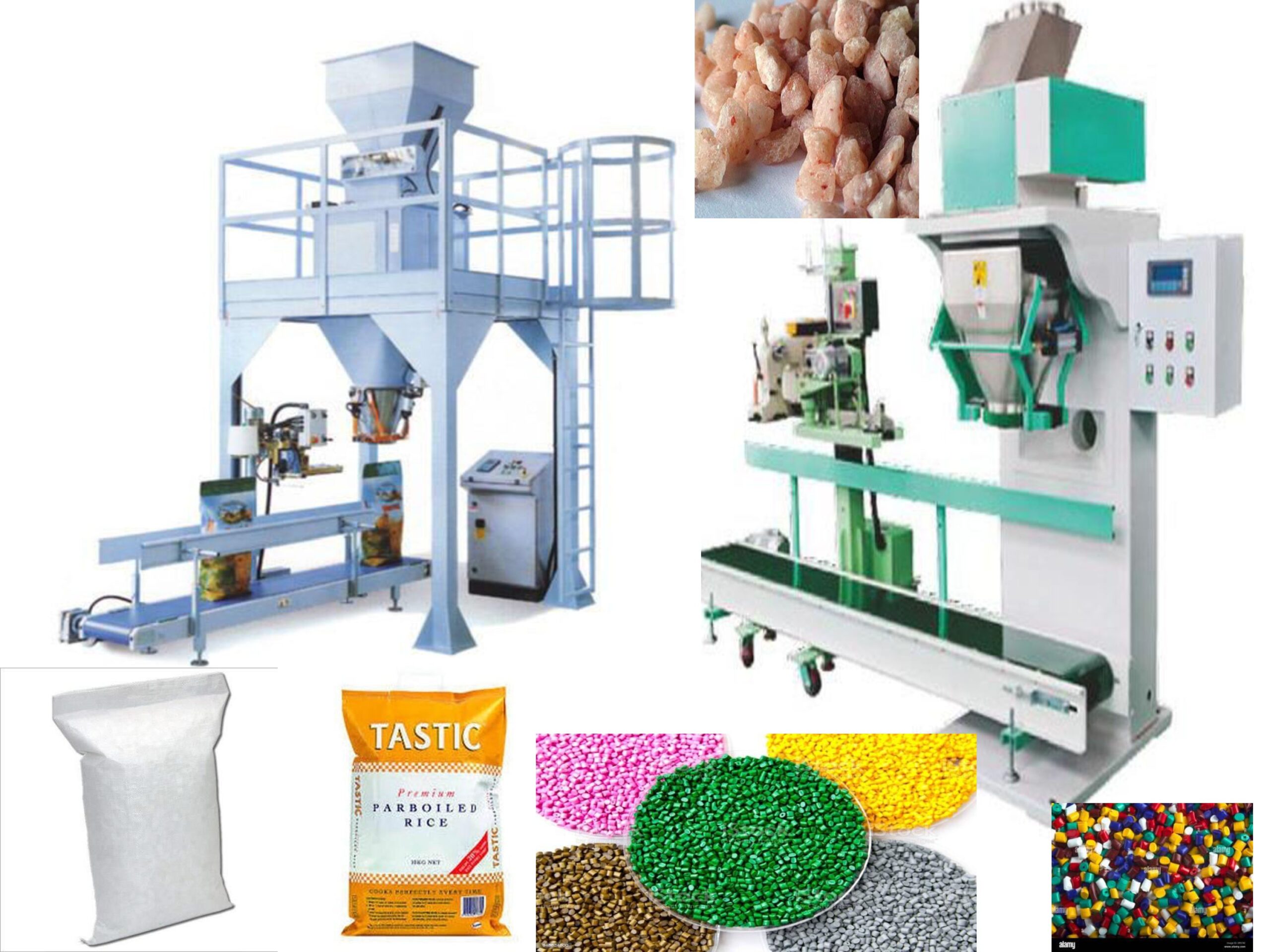

25 kg powder filling machine supplier

A 25 kg powder filling machine is a specialized equipment designed to accurately fill bags with powdered substances, typically weighing 25 kilograms. These machines are widely used in industries such as food processing, pharmaceuticals, chemicals, and agriculture, where precise measurement and packaging are crucial for product quality and consistency.

Key Features:

1. Precision Filling: Equipped with precision weighing scales or volumetric fillers, ensuring accurate and consistent filling of powdered substances into each bag.

2. Adjustable Filling Range: The machine can be adjusted to accommodate various bag sizes, allowing for flexibility in packaging options.

3. High-Speed Operation: Engineered for efficiency, these machines can achieve high packaging speeds, maximizing production throughput.

4. Versatile Compatibility: Designed to handle a wide range of powdered substances, including flour, sugar, spices, chemicals, and pharmaceutical powders.

5. Customizable Settings: Adjustable parameters allow for customization of filling speed, bag size, and sealing options to meet specific production requirements.

6. User-Friendly Interface: Intuitive controls and touch-screen interfaces facilitate easy operation, monitoring, and adjustment of the packaging process, reducing training time for operators.

7. Robust Construction: Built with durable materials and components, ensuring reliability and longevity even in demanding industrial environments.

8. Safety Features: Incorporates safety mechanisms to prevent accidents and ensure operator safety during operation, including protective guards and emergency stop buttons.

9. Easy Maintenance: Designed for easy access to components and minimal maintenance requirements, reducing downtime and maximizing uptime for uninterrupted production.

Overall, a 25 kg powder filling machine provides a reliable and efficient solution for packaging powdered substances, enabling manufacturers to meet production demands while ensuring product integrity and consistency.