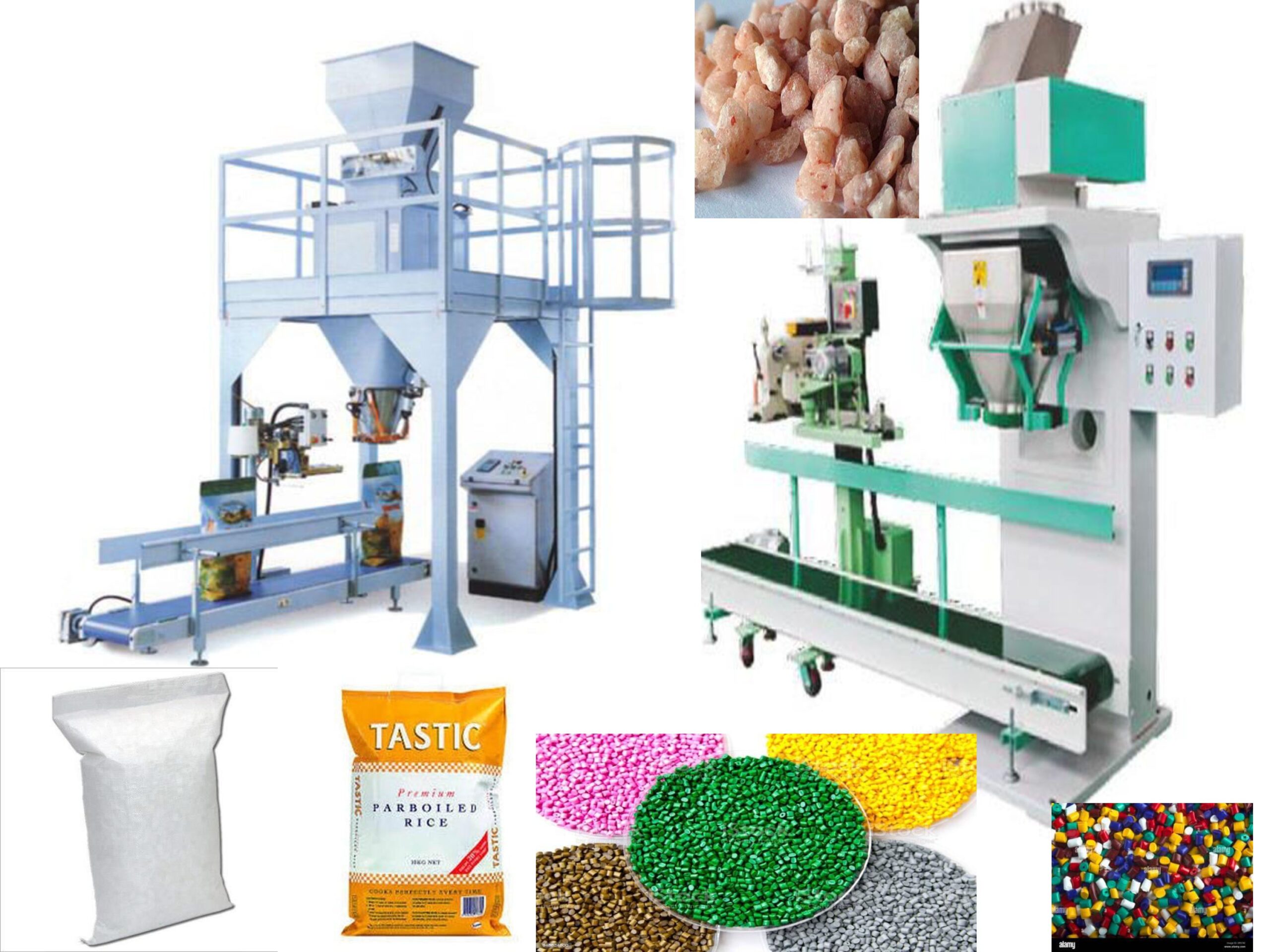

Polymer packaging machine

A polymer packaging machine is designed to efficiently package polymer-based products. It typically includes features such as automated sealing, cutting, and labeling, ensuring precise and secure packaging. Some machines offer adjustable settings for different polymer materials, thicknesses, and package sizes. Advanced models may incorporate smart sensors for quality control and user-friendly interfaces for easy operation. Overall, these machines streamline the packaging process, enhancing productivity and ensuring consistent, high-quality packaging for polymer products.

Polymer packaging machines often include features like:

1. Automated Sealing: Efficiently seals polymer packages to maintain product integrity.

2. Cutting Mechanism: Provides precise cutting for different package sizes and shapes.

3. Adjustable Settings: Allows customization for various polymer materials and thicknesses.

4. Labeling Capability: Integrates labeling systems for clear product identification.

5. Quality Control Sensors: Smart sensors for detecting and addressing packaging defects.

6. User-Friendly Interface: Intuitive controls for easy operation and setup.

7. Versatility: Accommodates a range of package sizes and formats.

8. High-Speed Operation: Ensures rapid and efficient packaging production.

9. Durability and Reliability: Built with robust materials for long-lasting performance.

10. Safety Features: Incorporates safety mechanisms for operator protection.

These features collectively contribute to the effectiveness and efficiency of polymer packaging machines in various industrial applications.