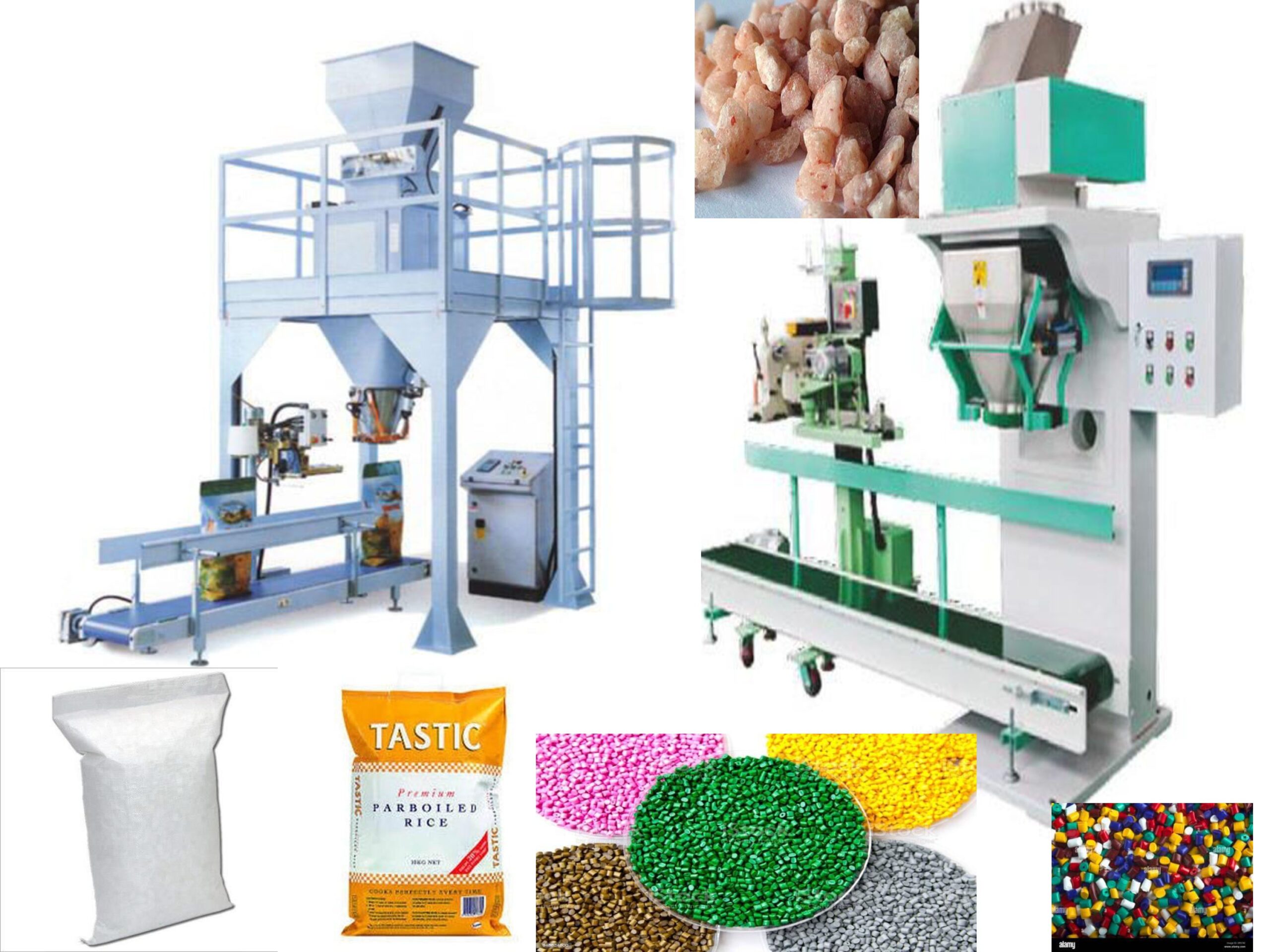

polymer Bagging Machine

A polymer bagging machine is designed for efficiently packaging polymer materials into bags. Its features typically include:

1. Precise Filling: The machine ensures accurate measurement and filling of polymer material into bags.

2. Bag Sealing: After filling, the bags are securely sealed to prevent contamination and maintain the integrity of the polymer.

3. Automation: These machines often have automated processes, reducing the need for manual labor and ensuring consistency.

4. Weighing System: Incorporates a weighing system to monitor and control the weight of polymer in each bag.

5. User Interface; Equipped with an interface for operators to control and monitor the packaging process easily.

6. Safety Measures: Includes safety features such as emergency stop buttons and guards to ensure safe operation.

7. Versatility: Designed to handle various polymer forms, including granules, pellets, or powder.

8. Efficiency: Optimizes the packaging process, improving productivity and minimizing material waste.

9. Customization: Allows for adjustment of settings to accommodate different bag sizes and polymer types.

10. Durability: Constructed with materials resistant to the corrosive nature of polymers, ensuring longevity.

These features collectively make a polymer bagging machine a valuable asset for industries dealing with polymer materials, providing efficient and reliable packaging solutions.