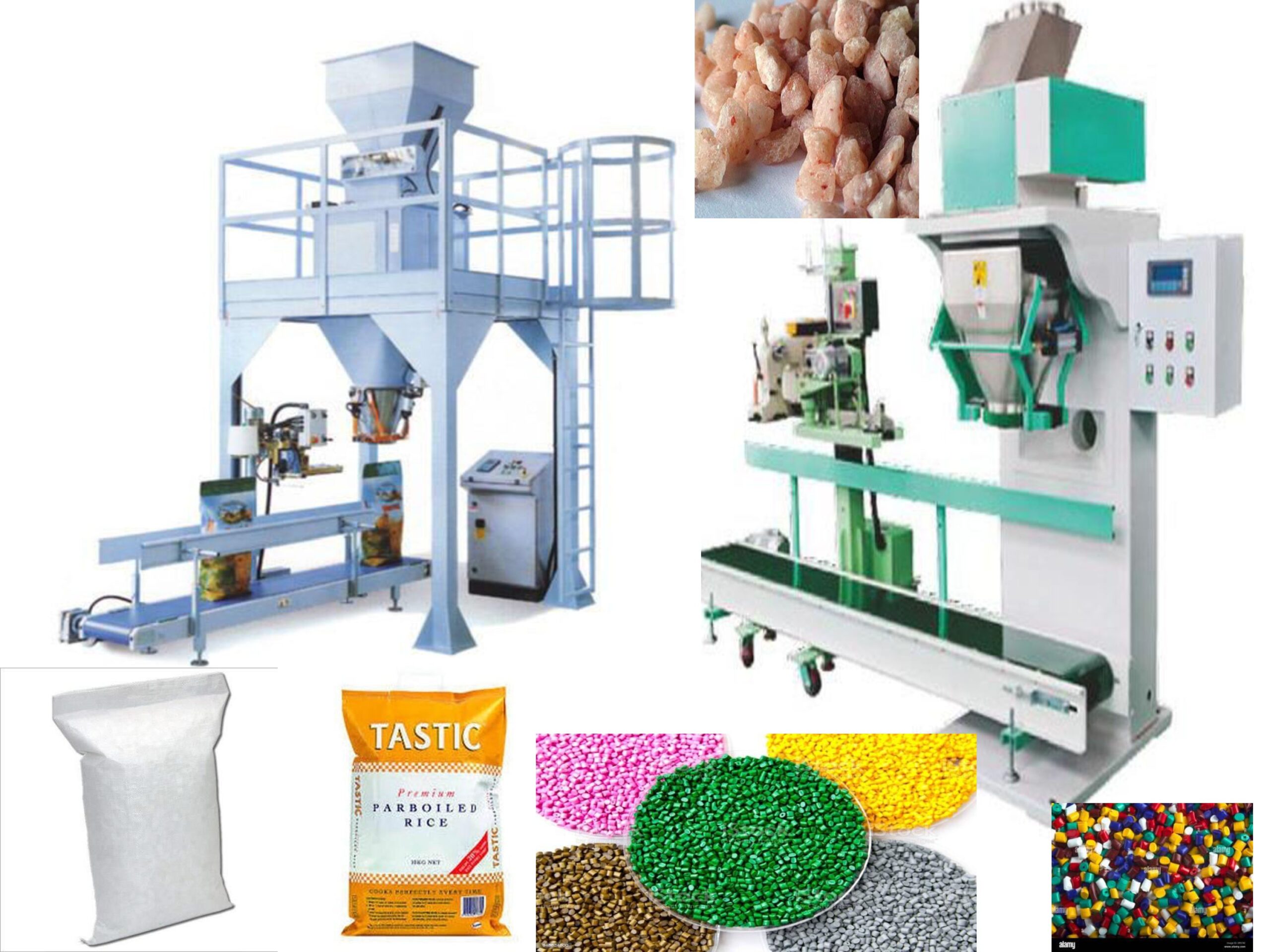

Bagging machine

Bagging machines, also known as baggers or bag packaging equipment, are automated systems designed to efficiently and accurately package products into bags. Key features include:

1. Versatility: Bagging machines can handle a wide range of products, including food items, pharmaceuticals, chemicals, and more.

2. Speed and Efficiency: These machines are capable of high-speed packaging, improving production efficiency and reducing labor costs.

3. Precision Weighing: Many bagging machines include precision weighing systems to ensure accurate measurement and consistent packaging.

4. Customization Options: Adjustable settings allow for various bag sizes and packaging configurations, catering to different product requirements.

5. User-Friendly Interface: Intuitive control panels make it easy for operators to set parameters, monitor production, and troubleshoot issues.

6. Integration Capabilities: Bagging machines can often be integrated into larger production lines, connecting seamlessly with other equipment for a streamlined manufacturing process.

7. Sealing Mechanisms: These machines incorporate sealing mechanisms to securely close and protect the contents of the bags. Common sealing methods include heat sealing and ultrasonic sealing.

8. Durable Construction: Built with robust materials, bagging machines are designed for durability and reliability in industrial settings.

9. Safety Features: Equipped with safety measures such as emergency stops and sensors to enhance worker safety.

10. Maintenance Alerts: Some advanced models include diagnostic features that provide alerts for maintenance needs, ensuring the longevity of the machine.

Overall, bagging machines play a crucial role in automating the packaging process, offering efficiency, consistency, and adaptability across various industries.