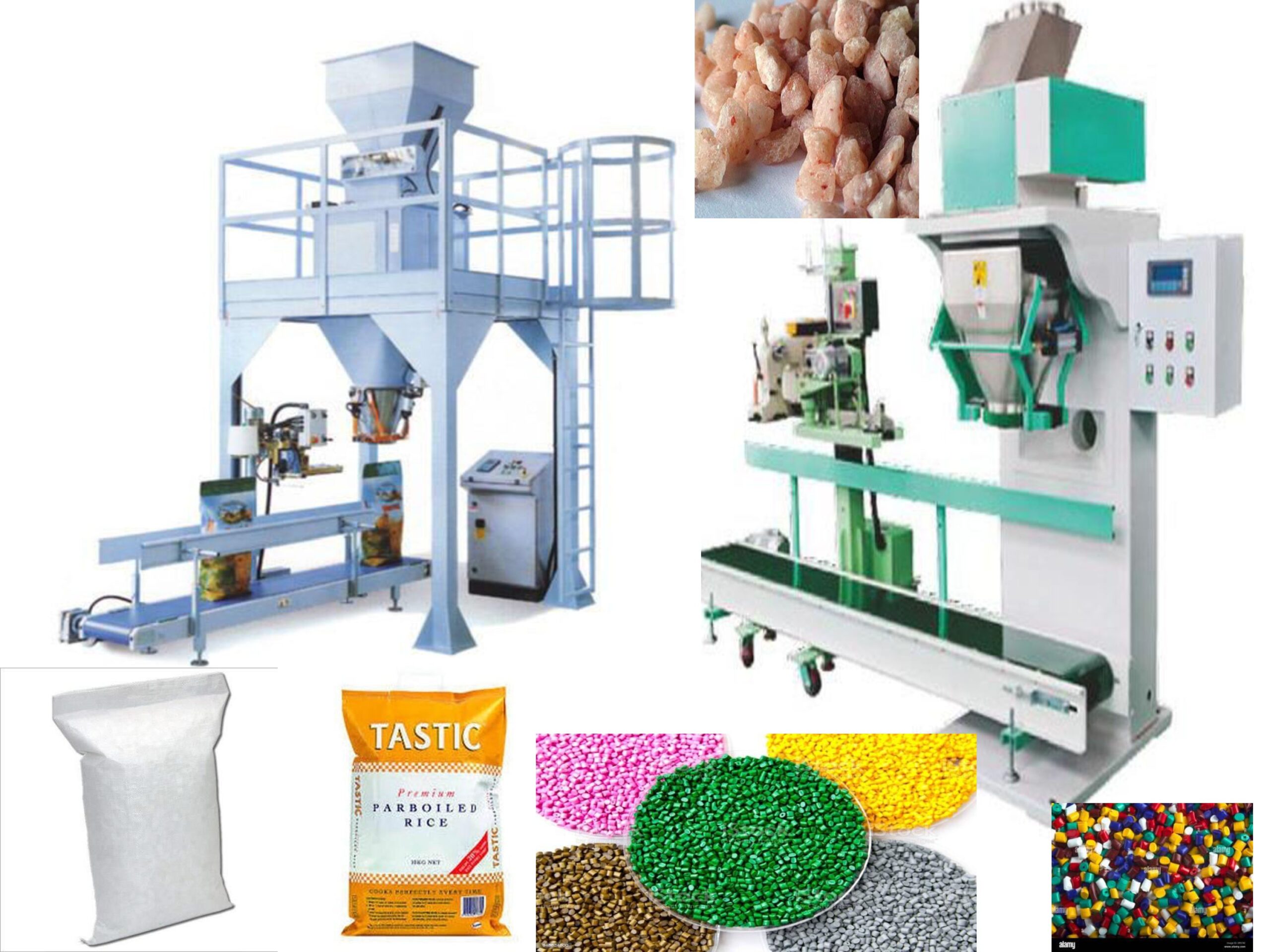

Bagging machine manufacturer

Our bagging machine is a state-of-the-art solution designed to streamline the packaging process across various industries. With its advanced technology and robust construction, our machine ensures efficient and precise bagging of a wide range of materials, from granules and powders to grains and chemicals. Whether you require bagging for polymer, masterbatch, PVC granules, plastic pellets, fertilizer, wheat, rice, pulses, grains, or chemical powders, our machine offers versatile and reliable performance.

Features:

1. Versatility: Our bagging machine is capable of handling diverse materials and bag sizes, making it suitable for a wide range of industries.

2. High-Speed Operation: With its high-speed capabilities, our machine maximizes productivity while maintaining accuracy.

3. Precision Weighing: Advanced weighing technology ensures precise filling of each bag, minimizing product wastage.

4. User-Friendly Interface: Intuitive controls and a user-friendly interface make operation easy and efficient, reducing training time and errors.

5. Customizable Settings: Adjustable settings allow for customization according to specific packaging requirements, ensuring optimal performance.

6. Durable Construction: Built with quality materials and components, our machine is designed for long-term reliability and minimal downtime.

7. Safety Features: Integrated safety features protect operators and prevent accidents during operation, prioritizing workplace safety.

8. Easy Maintenance: Simple maintenance procedures and accessible components facilitate quick troubleshooting and upkeep, minimizing downtime.

9. Compact Design: Space-saving design allows for easy integration into existing production lines or limited workspace environments.

10. Compliance: Our bagging machine adheres to industry standards and regulations, ensuring compliance with quality and safety requirements.

Specifications:

• Bag Types: Open-mouth bags, valve bags, FIBC (Flexible Intermediate Bulk Container)

• Bag Materials: Paper, plastic, woven polypropylene, jute, FIBC

• Bag Sizes: Adjustable, customizable according to requirements

• Filling Capacity: Customizable, ranging from a few grams to several kilograms

• Speed: Variable, depending on material and bag size, ranging from X bags per minute to Y bags per minute

• Power Requirements: Z volts, A phase, B Hz

• Dimensions: Length x Width x Height (in millimeters or inches)

• Weight: Approximate weight in kilograms or pounds

• Control System: PLC (Programmable Logic Controller) with touchscreen interface

• Operating Environment: Temperature, humidity, and other relevant conditions for optimal performance

This description, along with the listed features and specifications, highlights the capabilities and benefits of our bagging machine, positioning it as a reliable and efficient solution for various packaging needs.