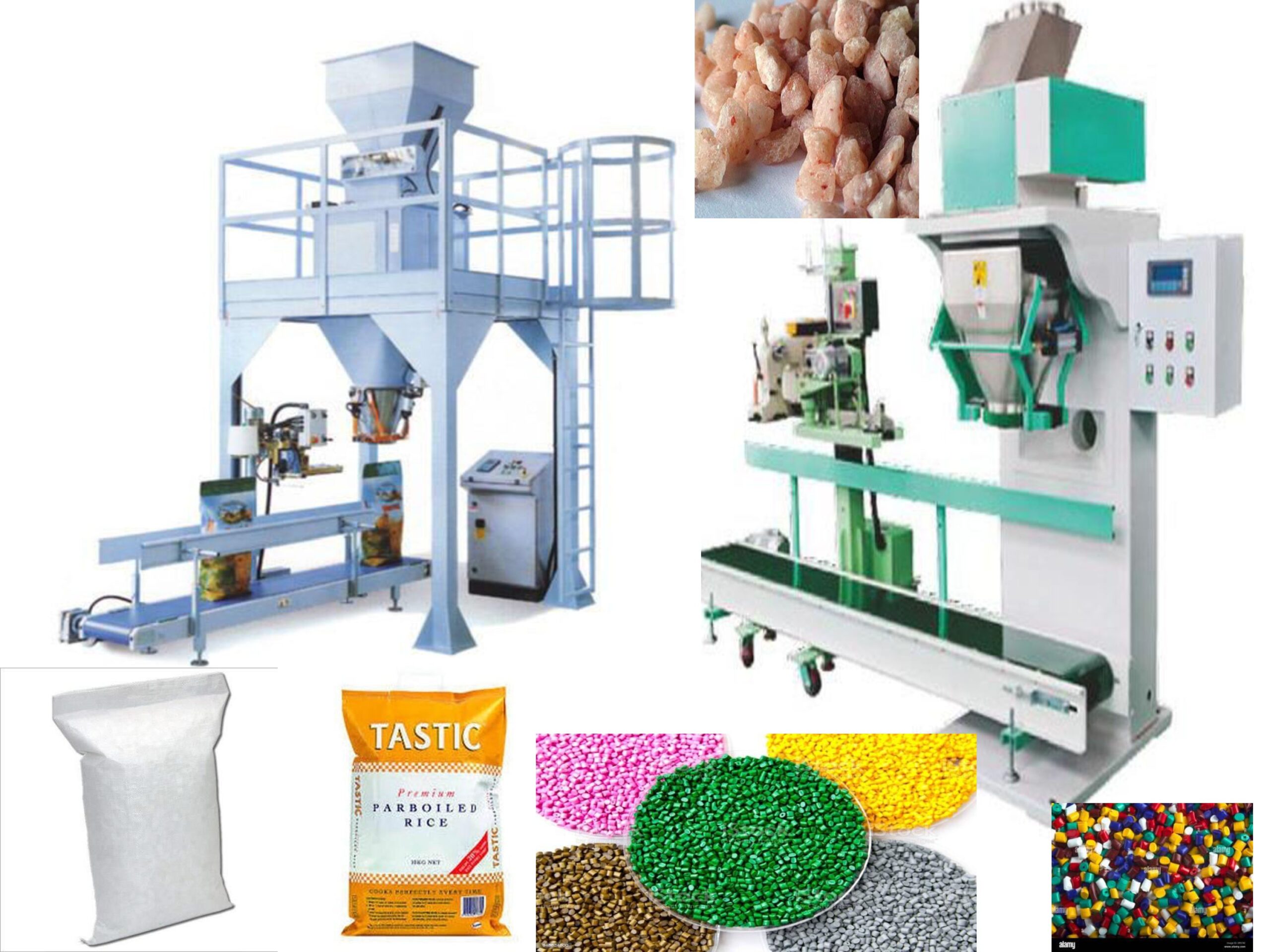

Weighing And Bagging machine

Weighing and bagging machines are advanced systems that combine precision weighing with efficient packaging capabilities. Key features include:

1. Precision Weighing Technology: Integrated scales with high accuracy ensure precise measurement of product quantities, meeting quality standards and minimizing waste.

2. Versatile Applications: Suitable for a wide range of products, these machines handle diverse materials such as food, chemicals, and aggregates.

3. Automated Bagging: Streamlined packaging process with automated bagging functionality, reducing manual labor and increasing overall production efficiency.

4.Customizable Bag Sizes: Adjustable settings allow for flexibility in bag sizes, accommodating various product volumes and packaging requirements.

5. User-Friendly Interface: Intuitive control panels enable easy operation, parameter adjustments, and real-time monitoring, enhancing user convenience.

6. Integration Capabilities: Designed to seamlessly integrate with other production line equipment, promoting a cohesive and synchronized manufacturing process.

7. Quality Sealing Mechanisms: Incorporates reliable sealing methods, such as heat sealing or ultrasonic sealing, to ensure secure and tamper-resistant packaging.

8. Durable Construction: Built with robust materials, these machines withstand the demands of industrial environments, providing longevity and reliability.

9.Safety Features Equipped with safety measures like emergency stops and sensors, prioritizing the well-being of operators and maintaining a secure working environment.

10. Data Recording and Reporting: Some models offer data recording capabilities, allowing businesses to track production metrics and ensure quality control.

In essence, weighing and bagging machines offer a comprehensive solution, combining precision weighing and efficient packaging to optimize the packaging process across diverse industries.